Hey guys.

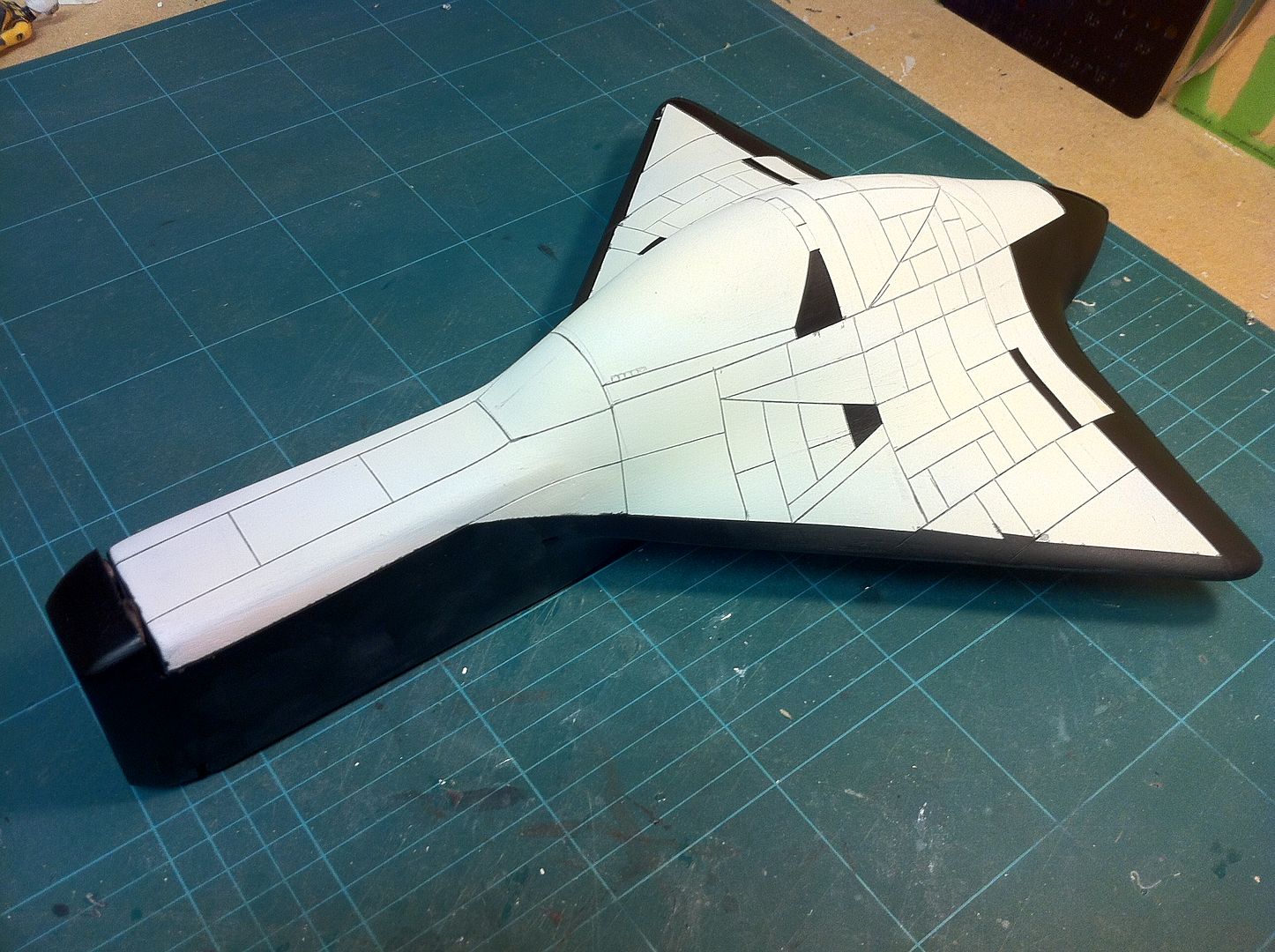

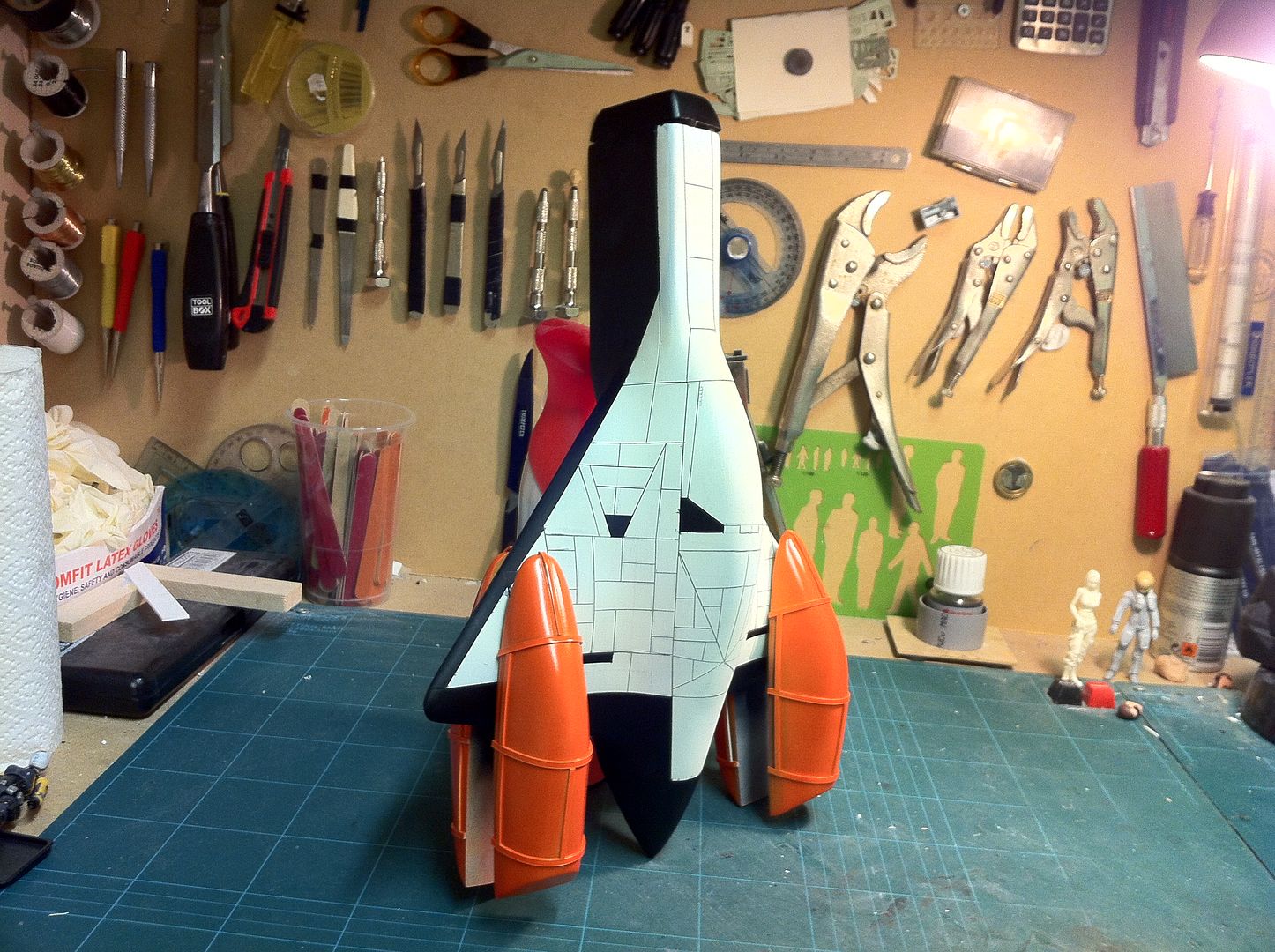

I started a quick project this week of a totally underscaled Comanche(Just a cheap toy alteration).

In making it(and in posting it over on the Hisstank), i realised there might be a few people out there who would like a Comanche in a scale that would be a nice companion piece for the True Heroes Apache(Which is about 1/28 in reality).

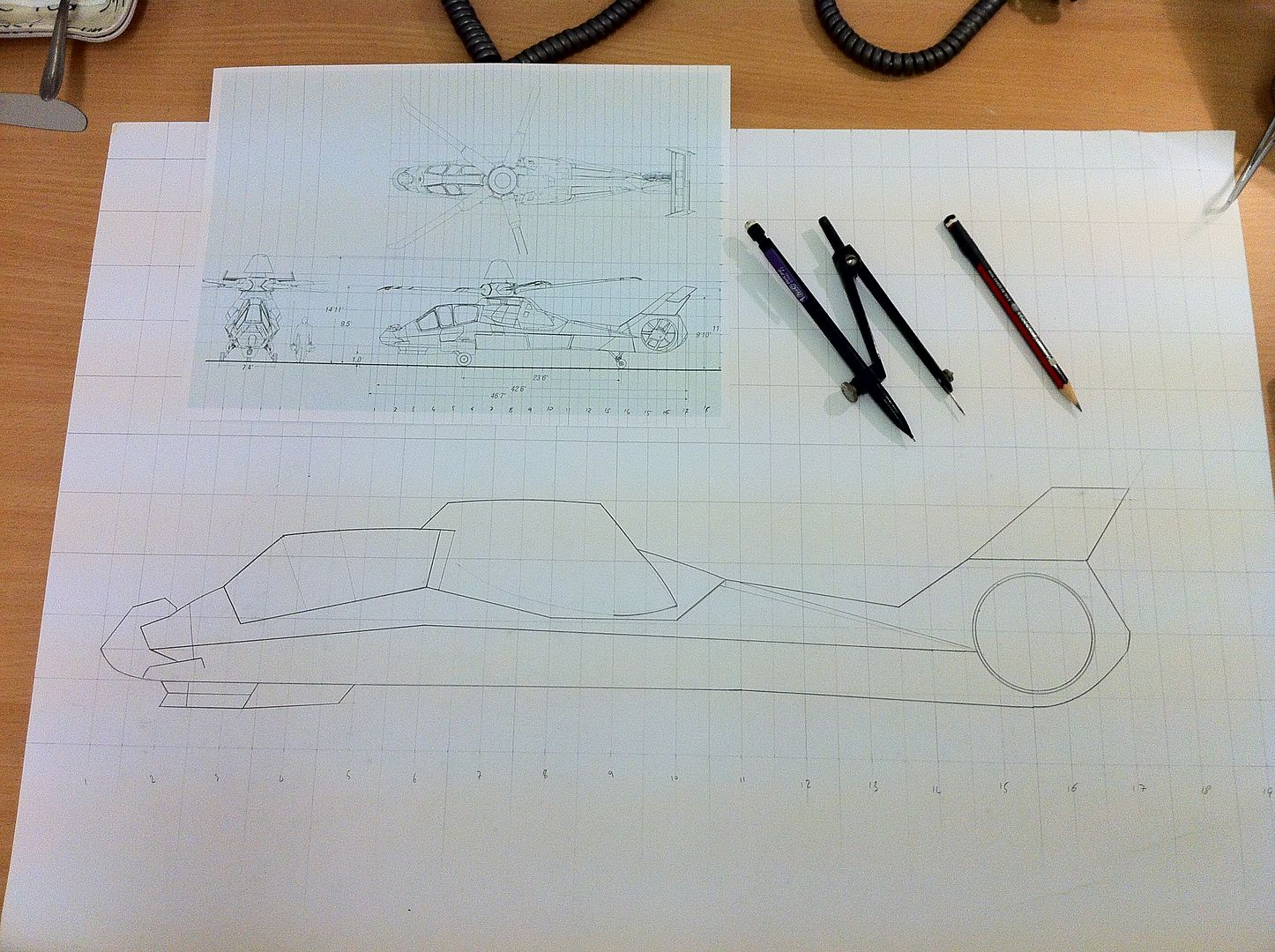

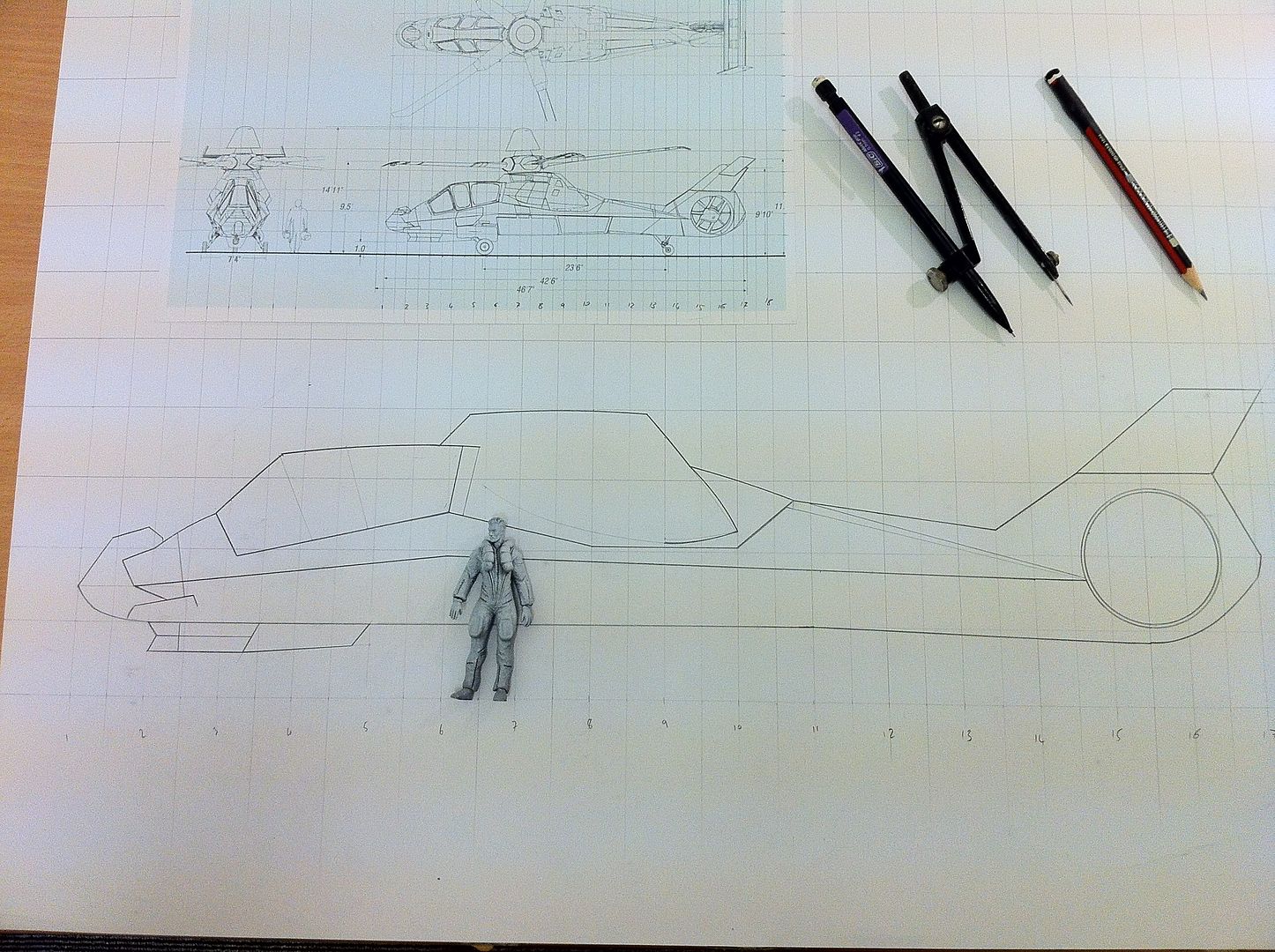

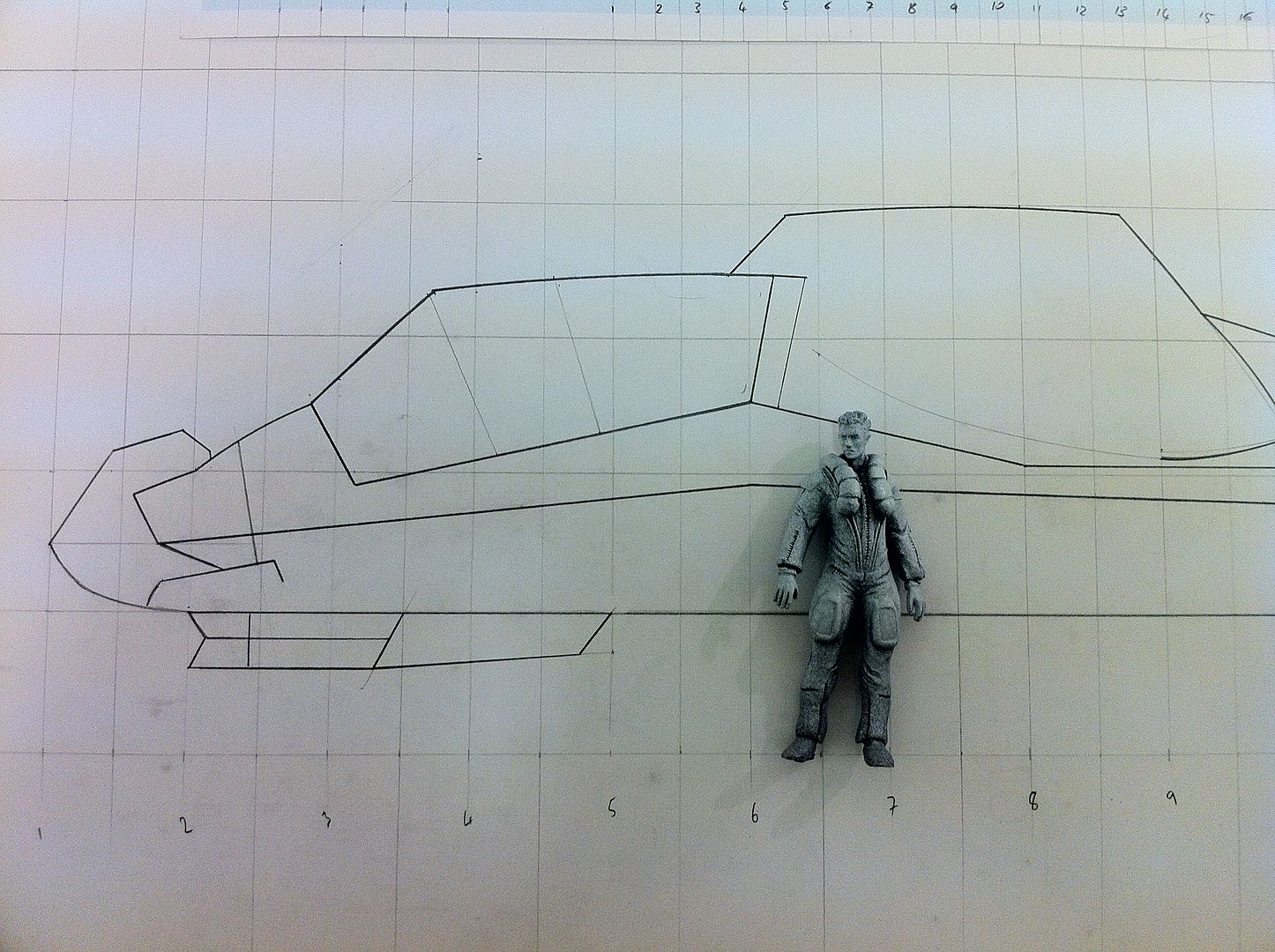

But after spending an hour or so with my digital calipers transposing a set of Comanche plans i found into 1/28... I started thinking that perhaps there might be more people who'd fancy a TRUE 1/18 Comanche hull for custom builds.

I am going to be making a vacform master pattern either way, and it will not take any more time to make it 79cm than it would to make it 55cm("True Heroes scale").

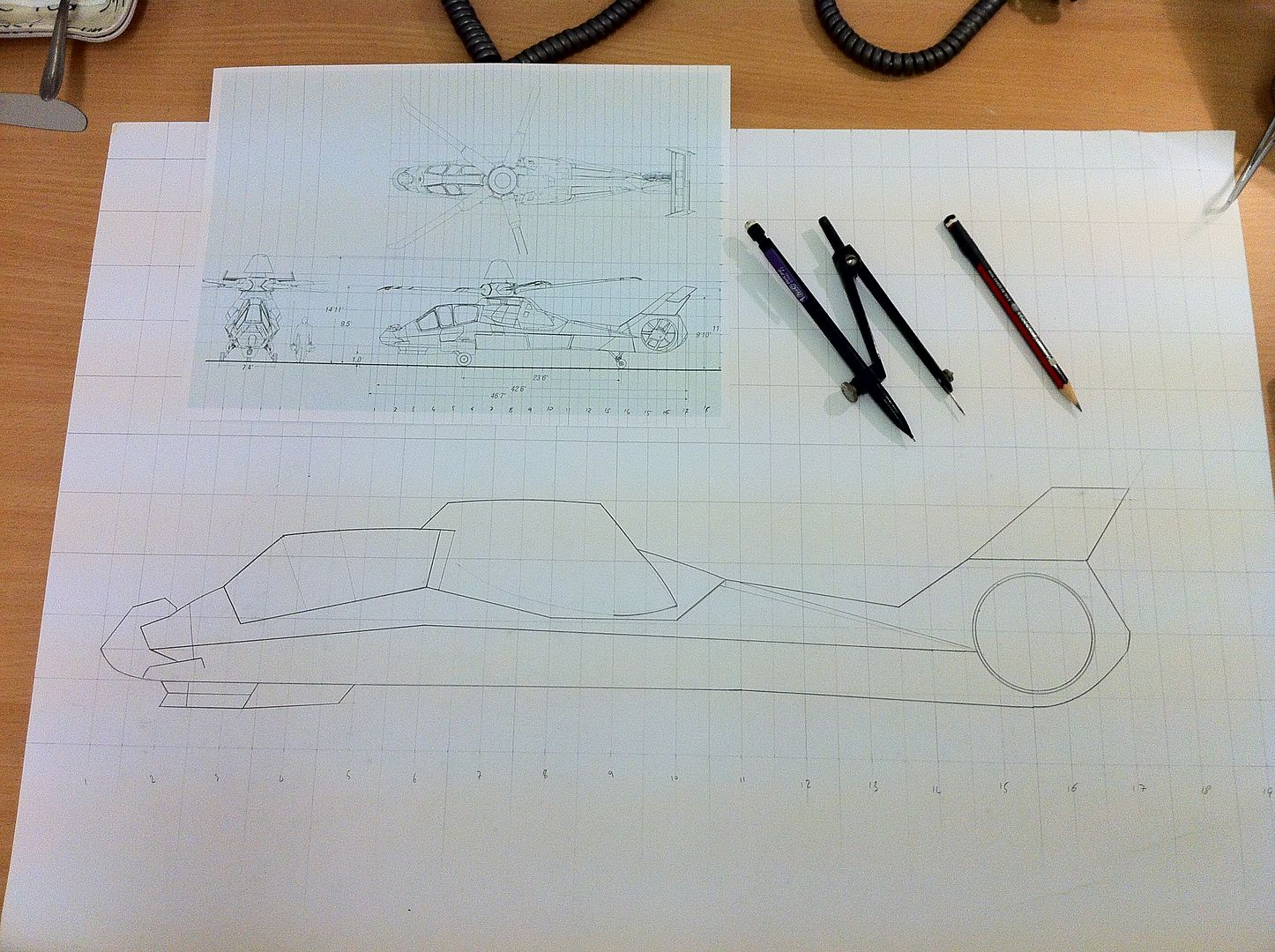

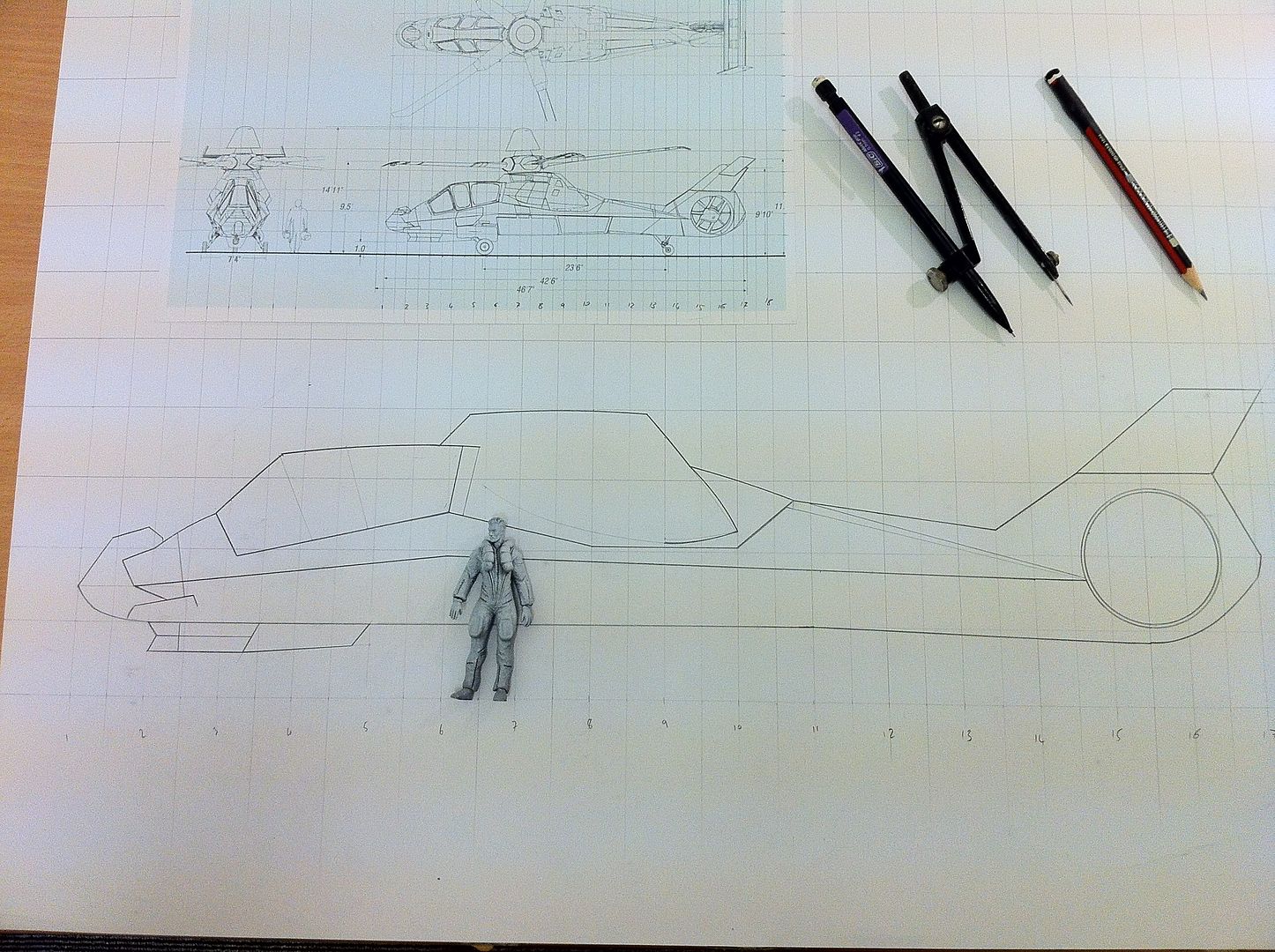

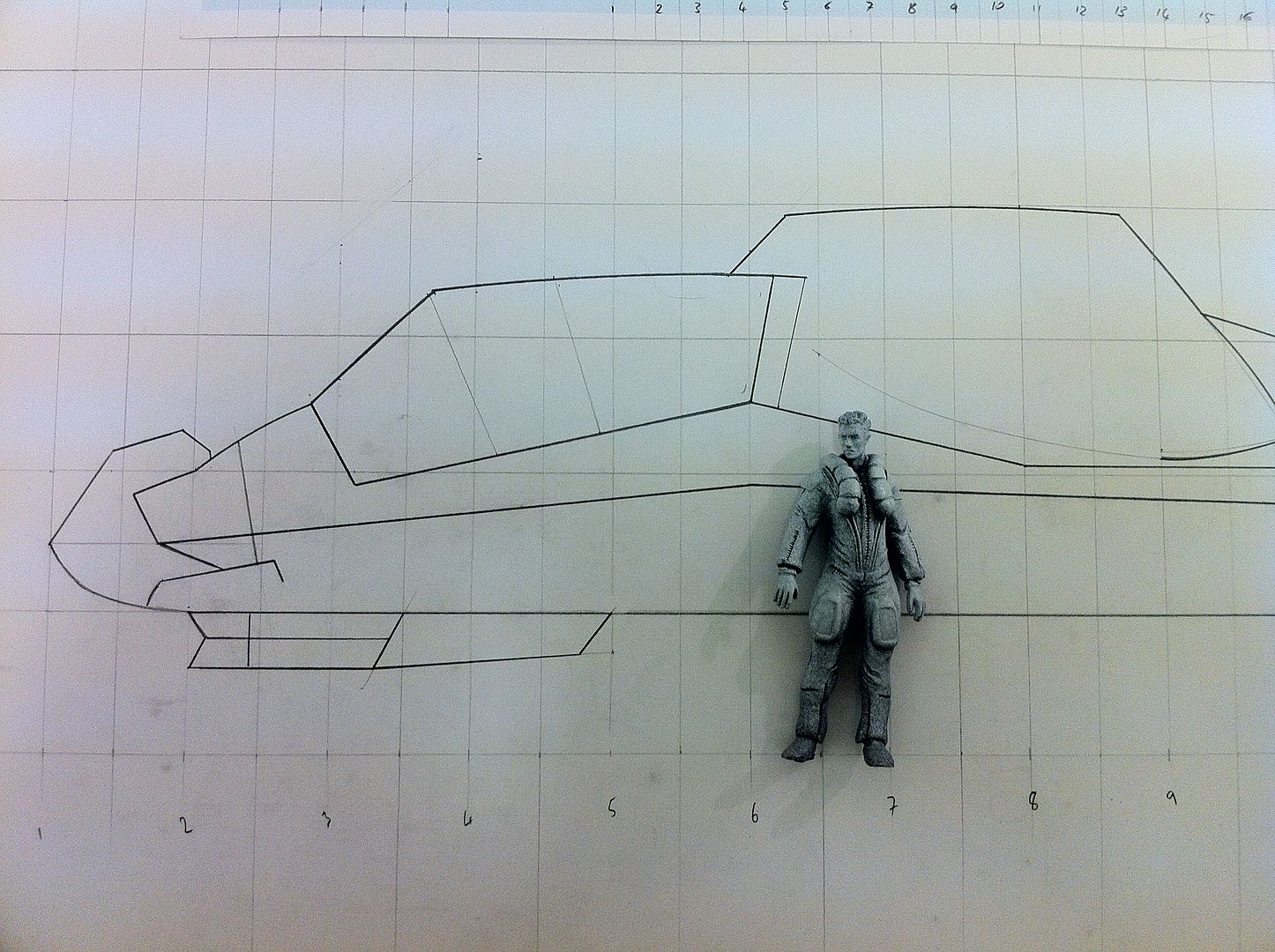

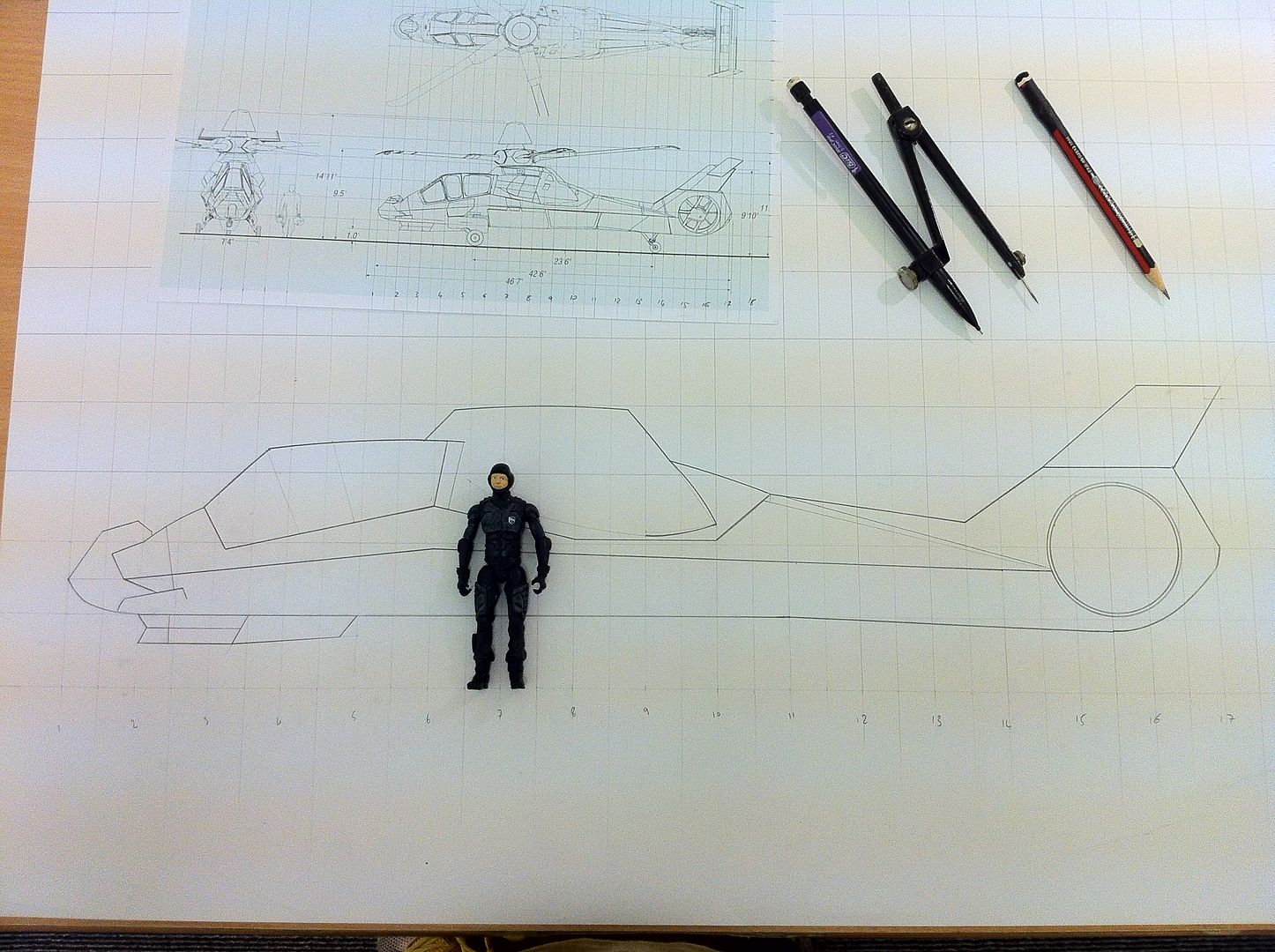

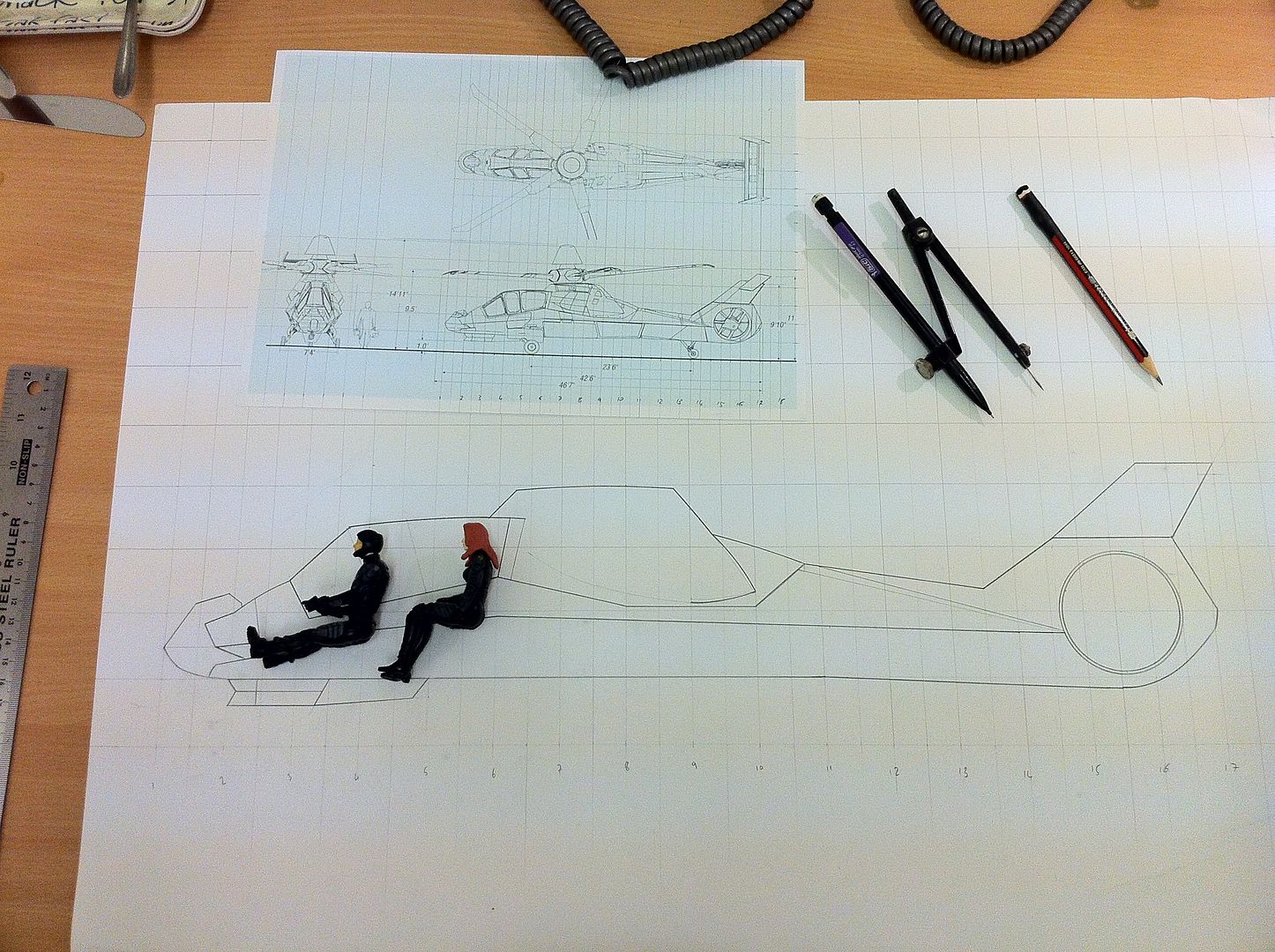

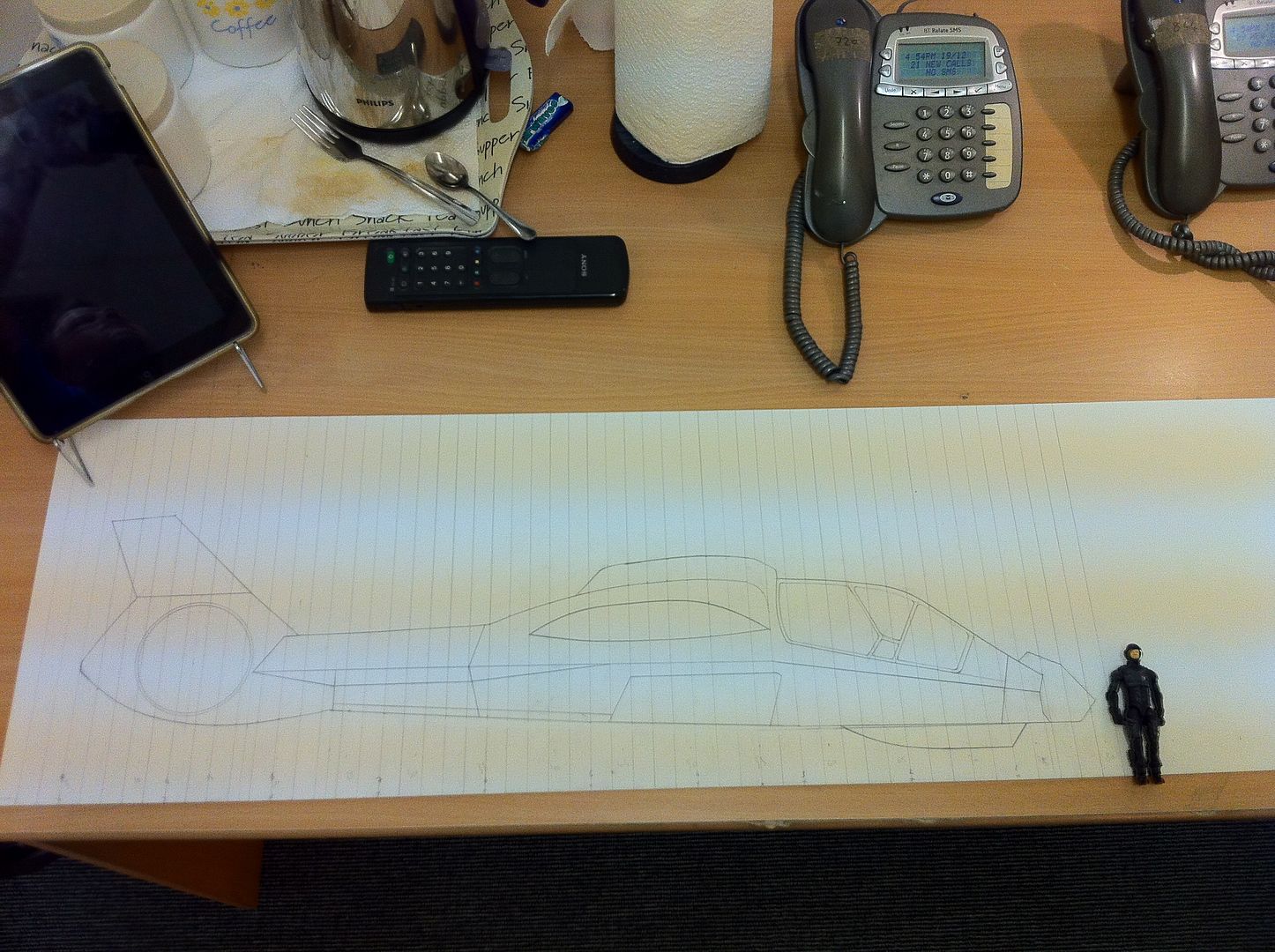

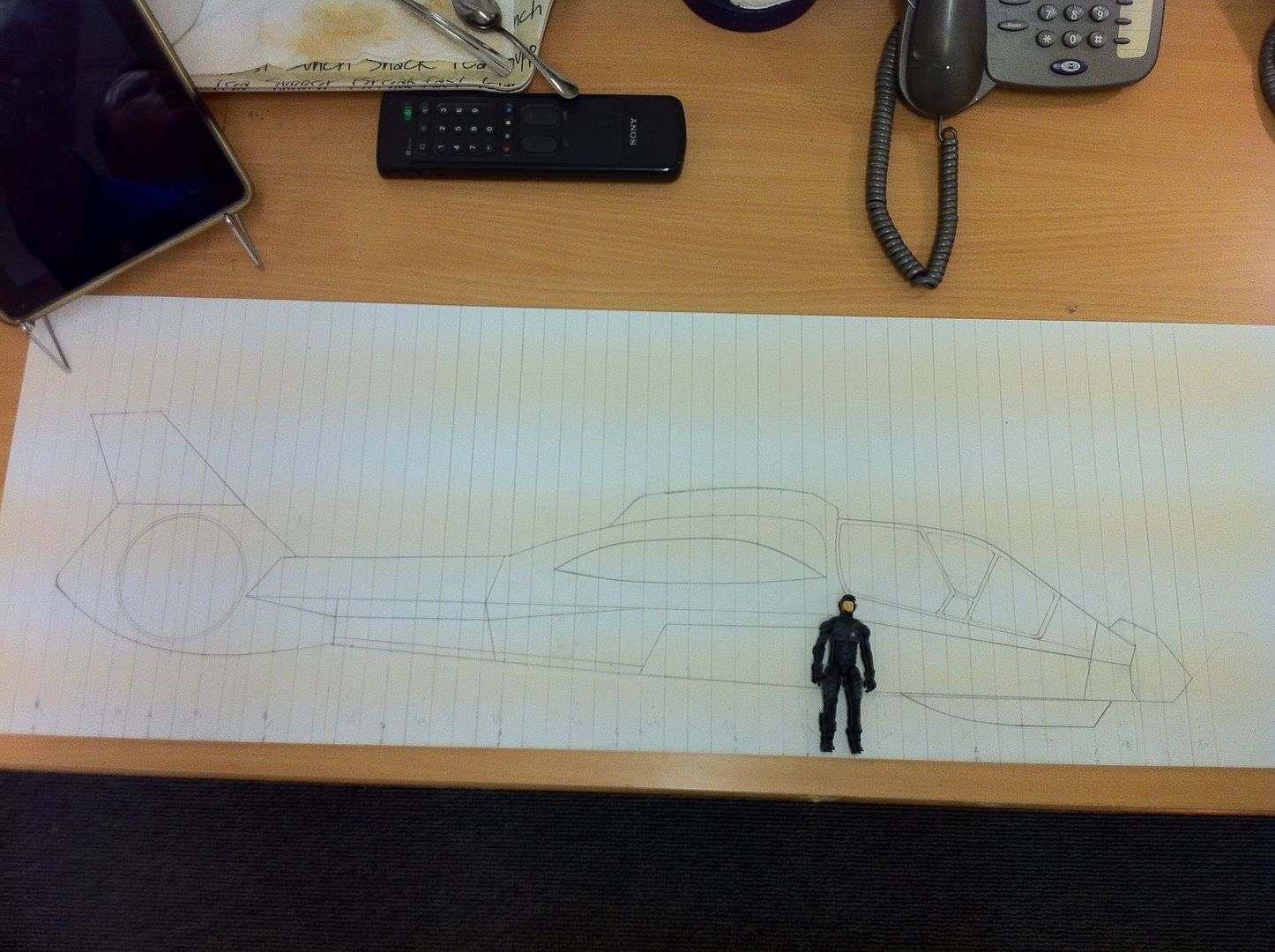

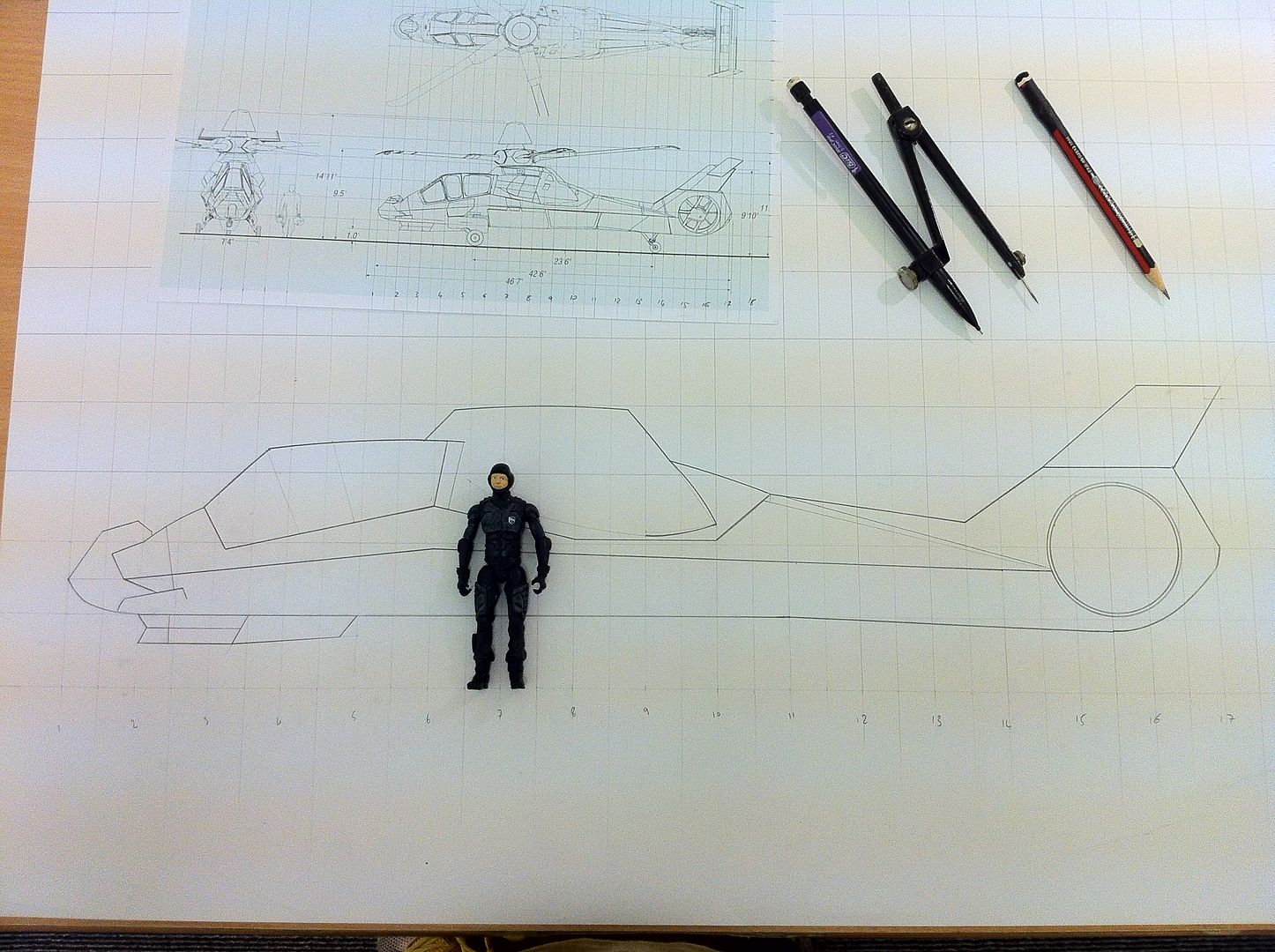

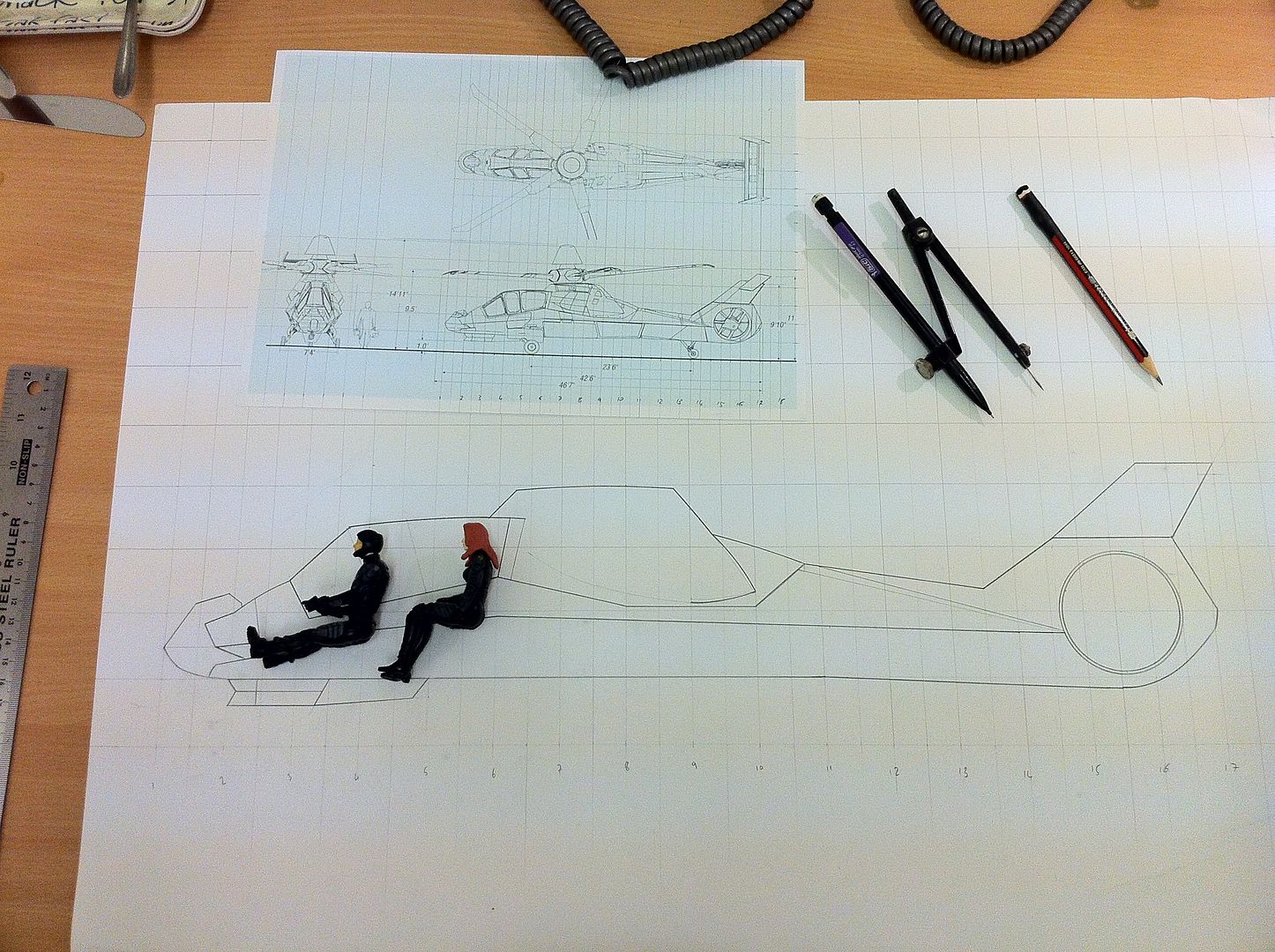

So i expect i know the answer people here will give, but would it be preferable to make it in 1/18? Or would it be a better companion for the Apache in "True Heroes" scale? Also, if anyone knows of a resource where i could get very good plans of the craft that would help. I was working from this image today at work.

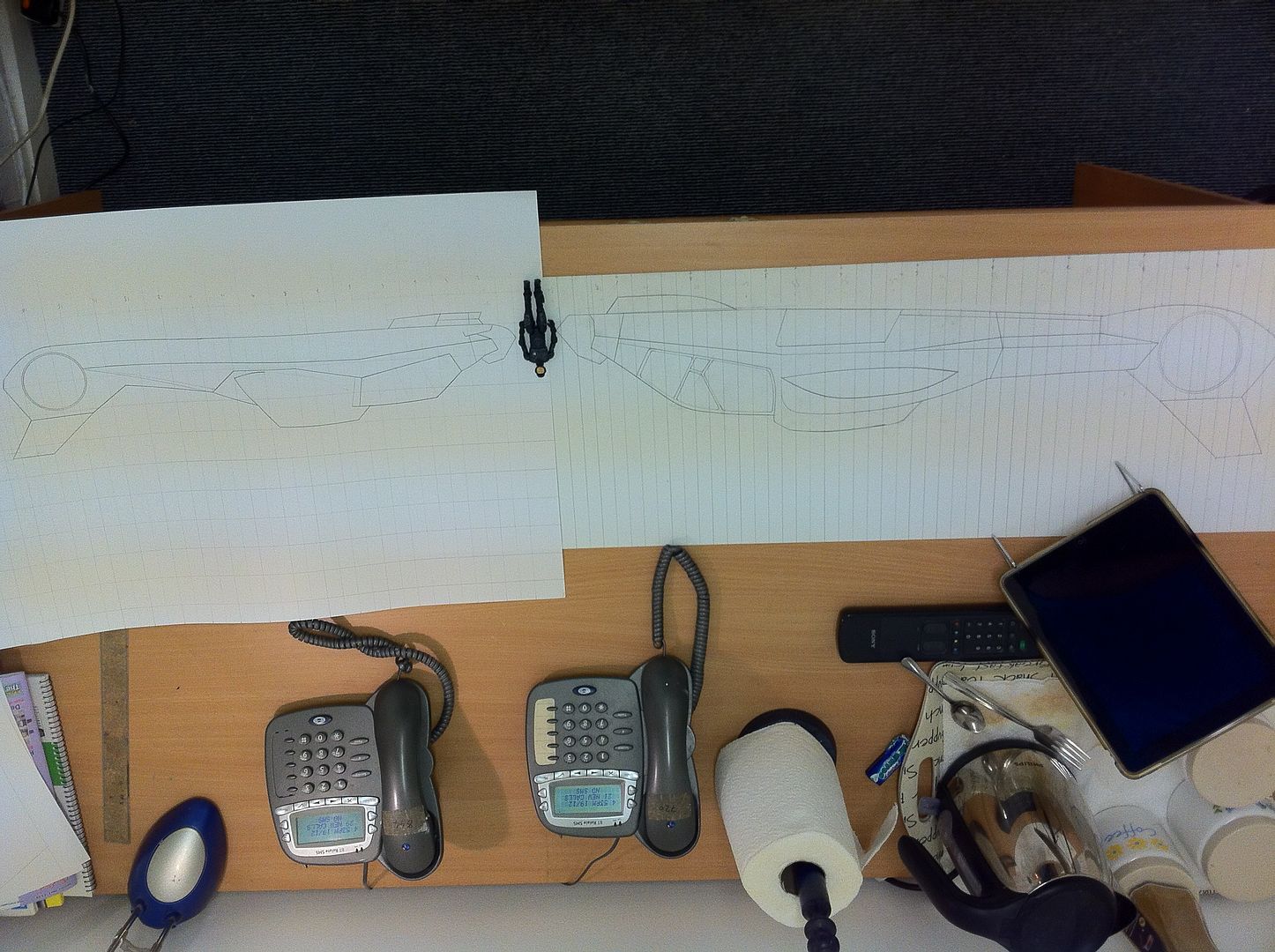

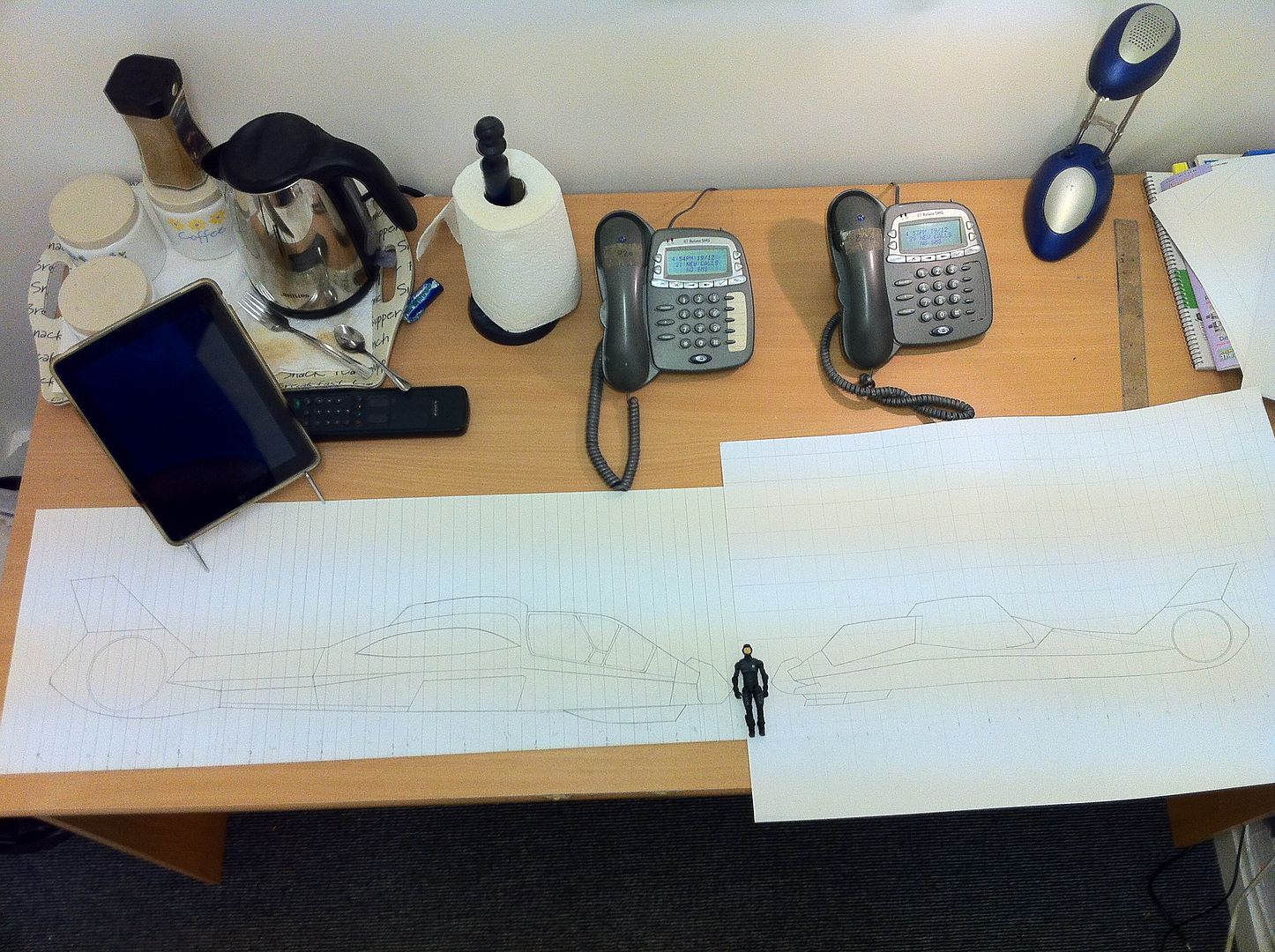

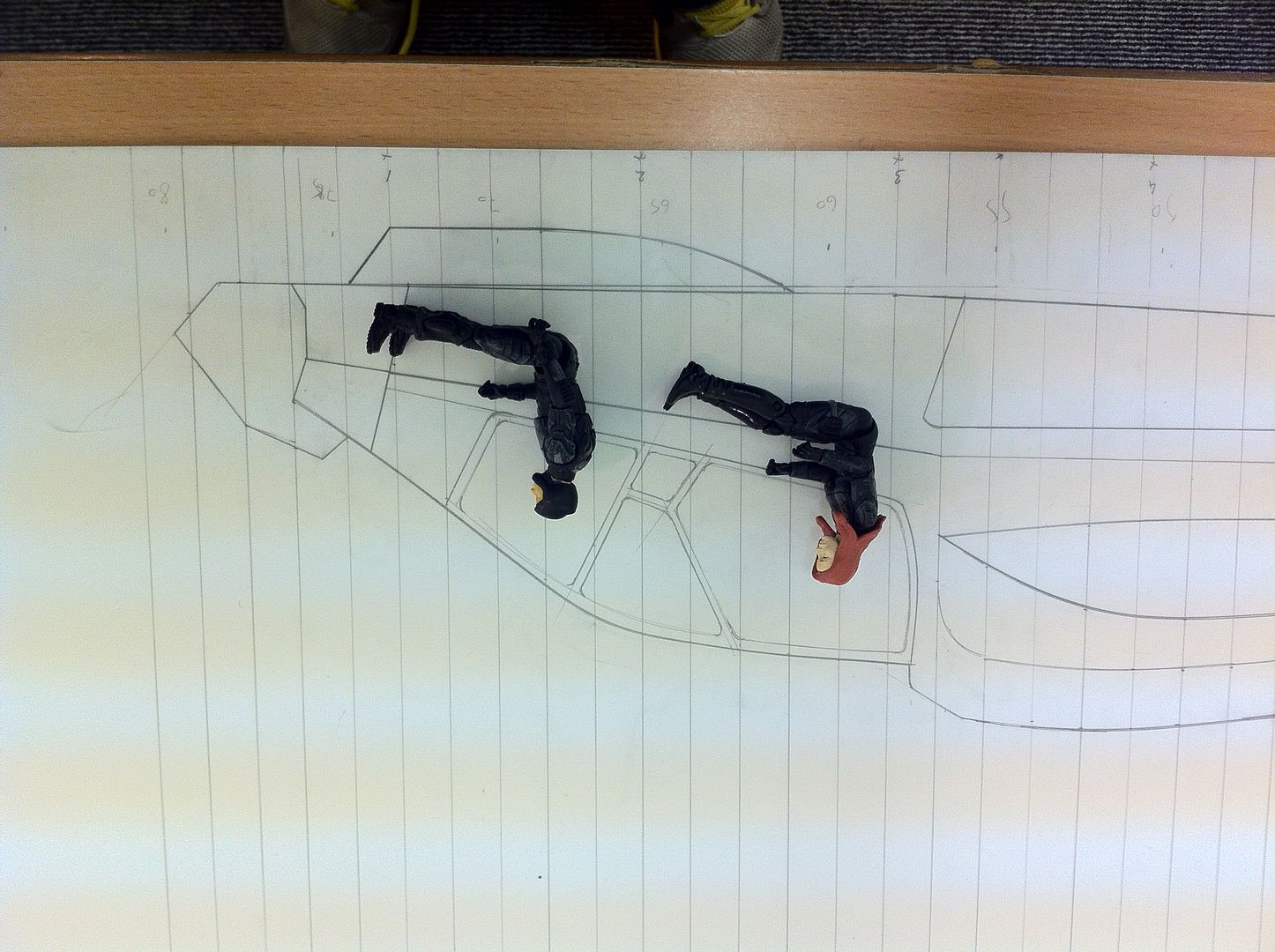

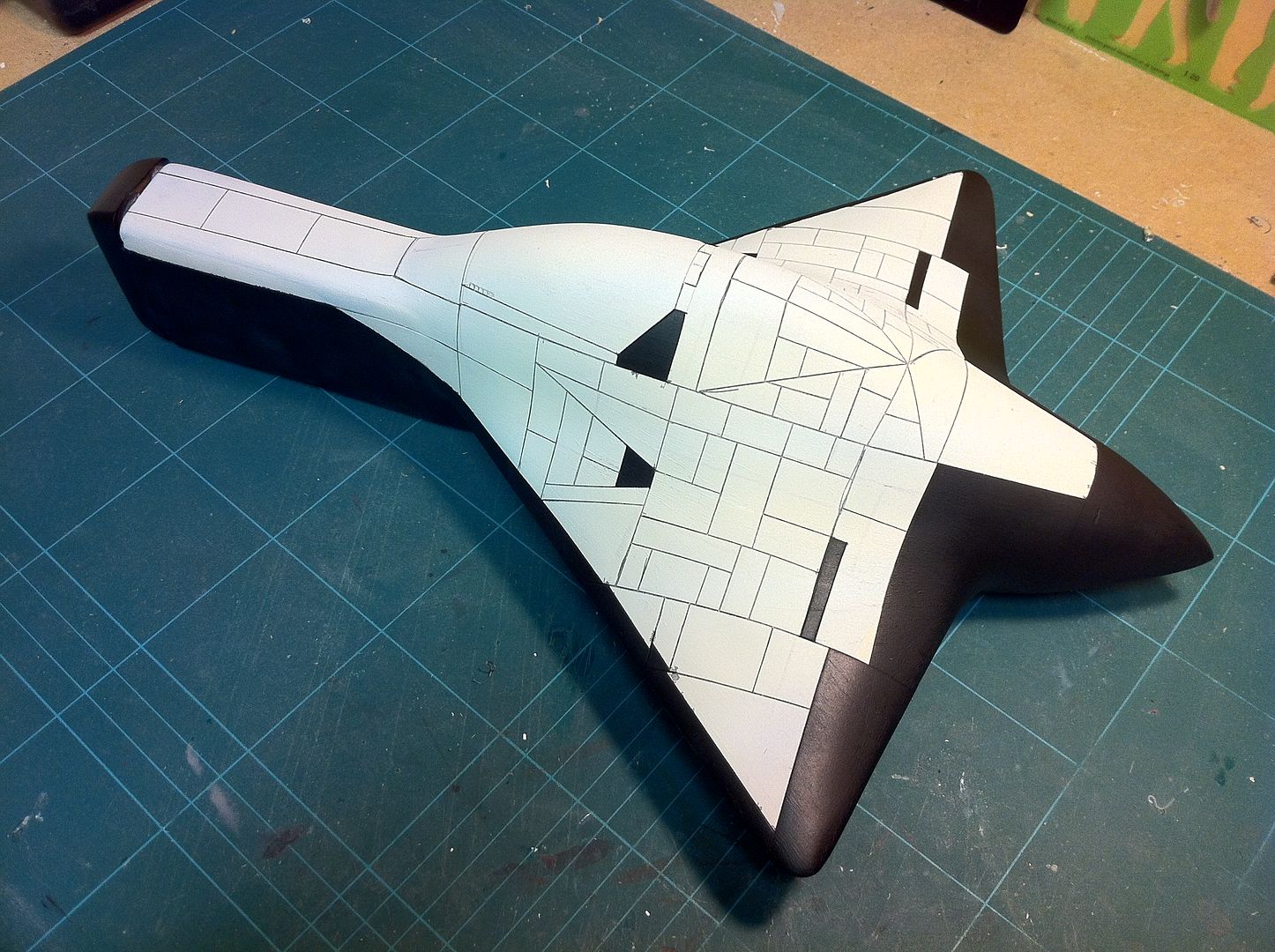

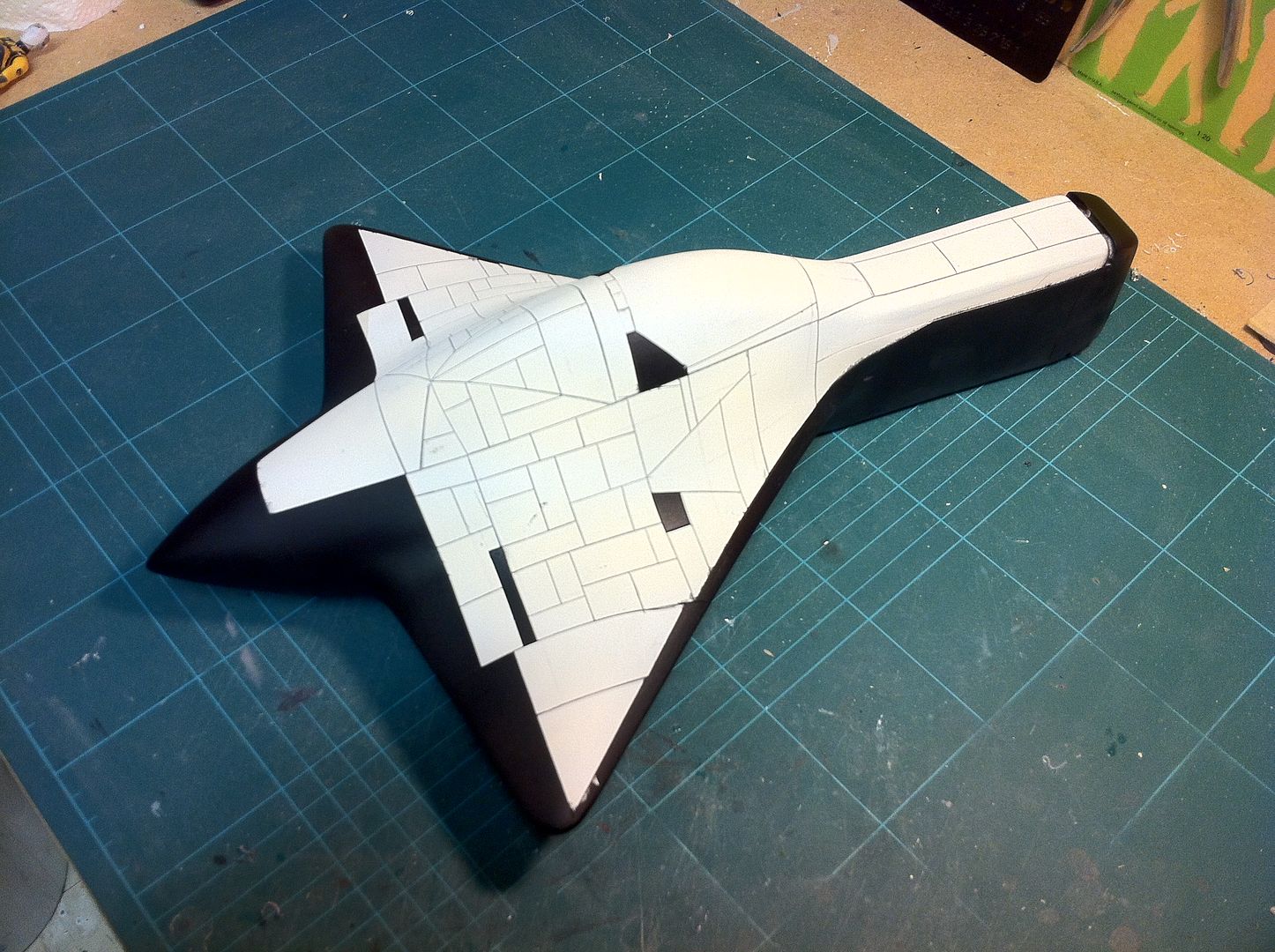

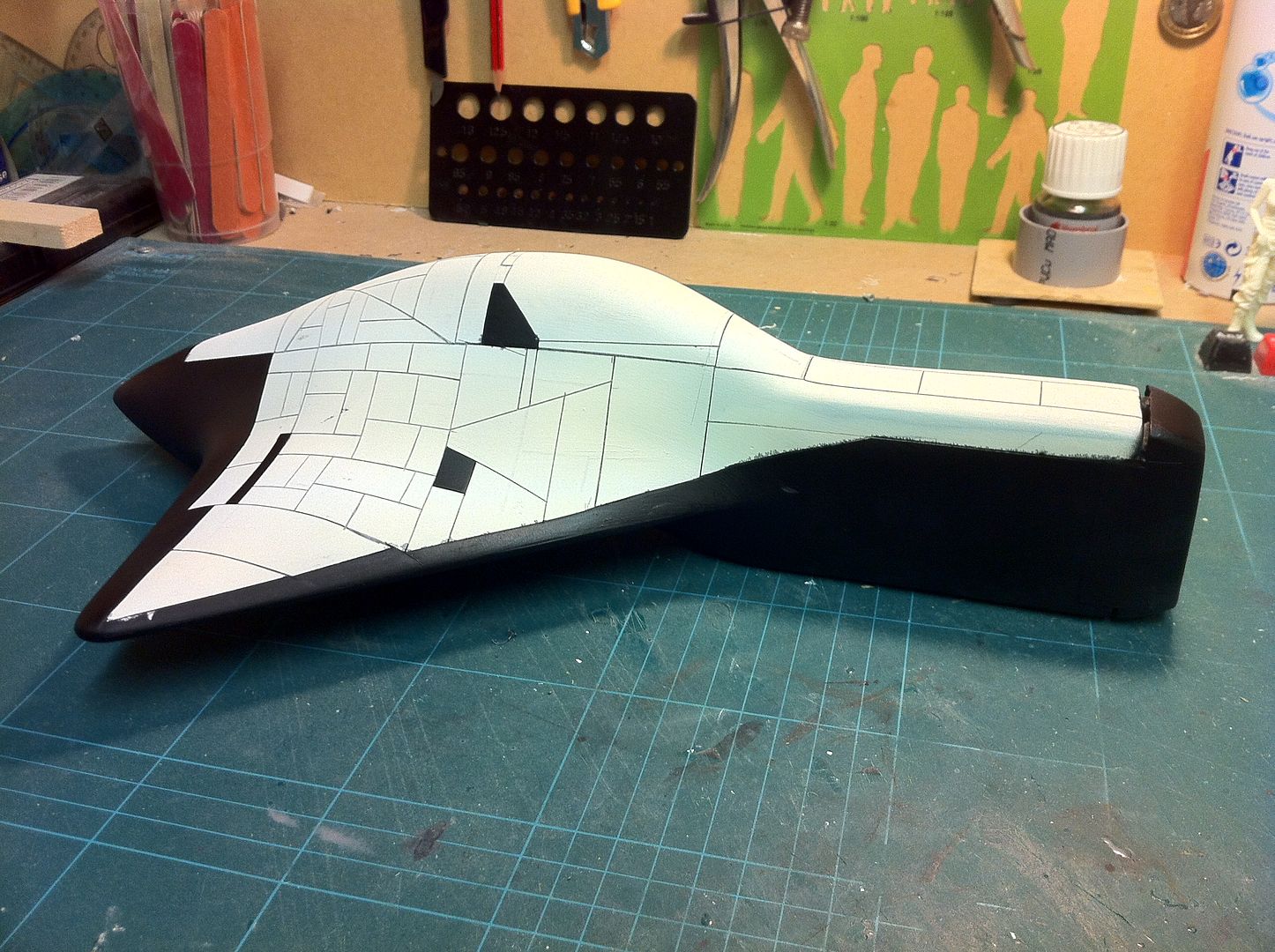

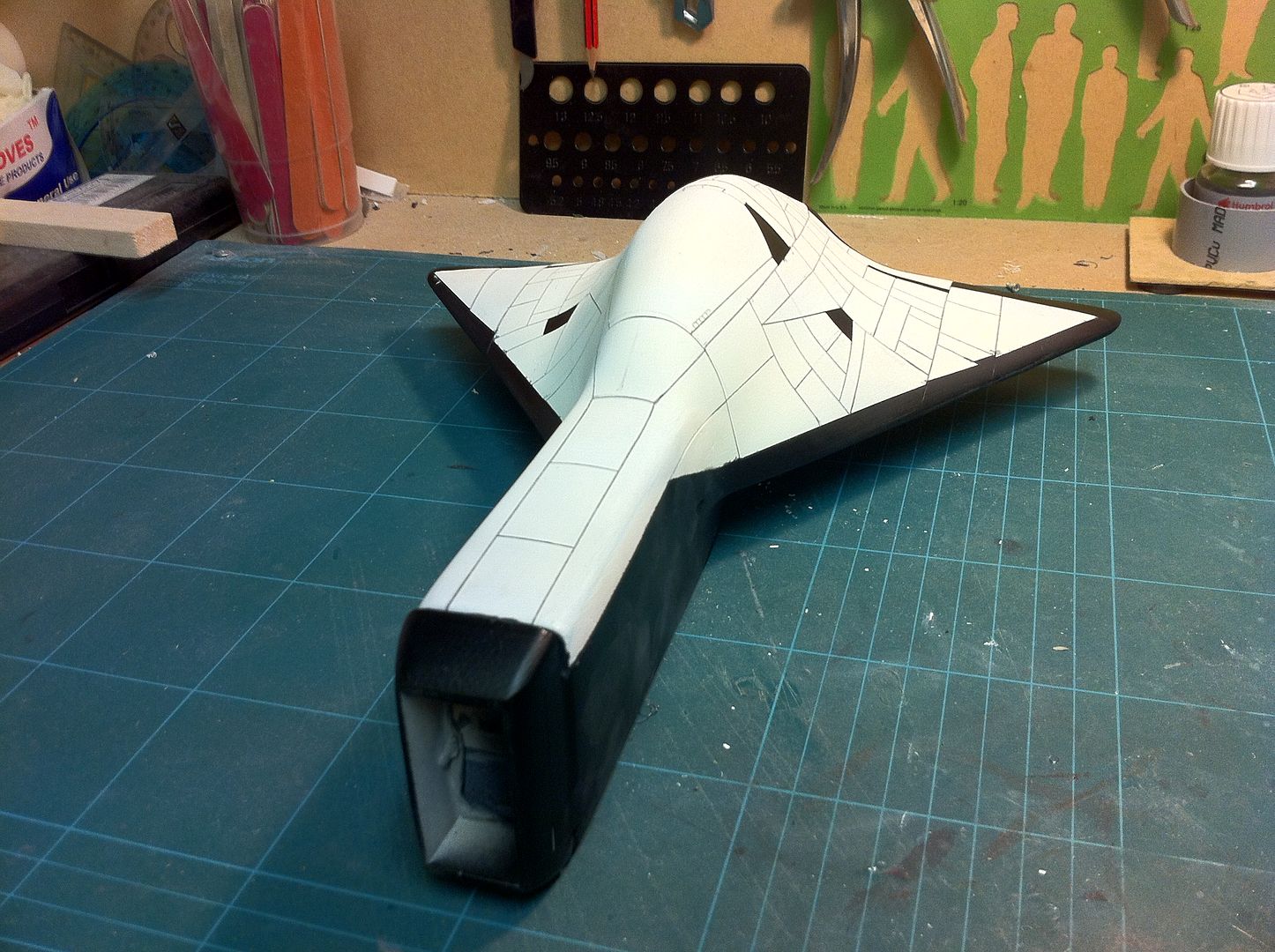

Here are pics of the drawings i did today at 55cm long as an idea(The little pilot figure shown in a couple of the images is closer to the proper scale of 1/28. Also shown is the crummy project that started this off and the True Heroes Apache, with the tails lined up to show the size difference of the two in the same scale):

I started a quick project this week of a totally underscaled Comanche(Just a cheap toy alteration).

In making it(and in posting it over on the Hisstank), i realised there might be a few people out there who would like a Comanche in a scale that would be a nice companion piece for the True Heroes Apache(Which is about 1/28 in reality).

But after spending an hour or so with my digital calipers transposing a set of Comanche plans i found into 1/28... I started thinking that perhaps there might be more people who'd fancy a TRUE 1/18 Comanche hull for custom builds.

I am going to be making a vacform master pattern either way, and it will not take any more time to make it 79cm than it would to make it 55cm("True Heroes scale").

So i expect i know the answer people here will give, but would it be preferable to make it in 1/18? Or would it be a better companion for the Apache in "True Heroes" scale? Also, if anyone knows of a resource where i could get very good plans of the craft that would help. I was working from this image today at work.

Here are pics of the drawings i did today at 55cm long as an idea(The little pilot figure shown in a couple of the images is closer to the proper scale of 1/28. Also shown is the crummy project that started this off and the True Heroes Apache, with the tails lined up to show the size difference of the two in the same scale):