I find this whole thread interesting.

I find that to be quite the compliment. Thanks.

I am currently working on a large project with wings.

I sure wish that I could vacuum form the wings but I would have to scribe panel lines on it.

40 times. For a one of would not be too bad.

That will be the Horten, right? The good think about vacforming in styrene is that it's cheap, easy to work with and easy to scribe. Of course, if you are selling buildups of the horten, i can imagine the pain it would be to scribe all the panels. But if you made vacform patterns of the wings, i am guessing about four hours on the pattern initially would see them sanded and primed and ready to go, and each set of wings would be about $20(Based on the size, and the place i get to do mine). If Your resin technique of adding the rods will stop them from drooping, plus you have the panel lines on already, then there's no real saving to be made, especially as you'd have to add the panel lines to each vacform separately. So that's a bonus of the technique you are using. But if you had made the Horten in two pieces. Hull top, and hull bottom, and vacformed the entire thing, it would be very light, and totally hollow. I reckon you would have had less fit issues with the cockpit seat frame. But on the flipside, you would have had to always scribe the panel lines...(And cut out the gear bay doors). That can be tiresome, no doubt about that. But not every technique works for every project. I just feel that there is not a market for a $300 Comanche. But a $60 one... Might just have people willing to scribe their own panel lines and build it themselves...(especially as the hull will weigh less than an unopened can of coke before you start).

It's all horses for courses.

Can't wait to see how the body turns out.

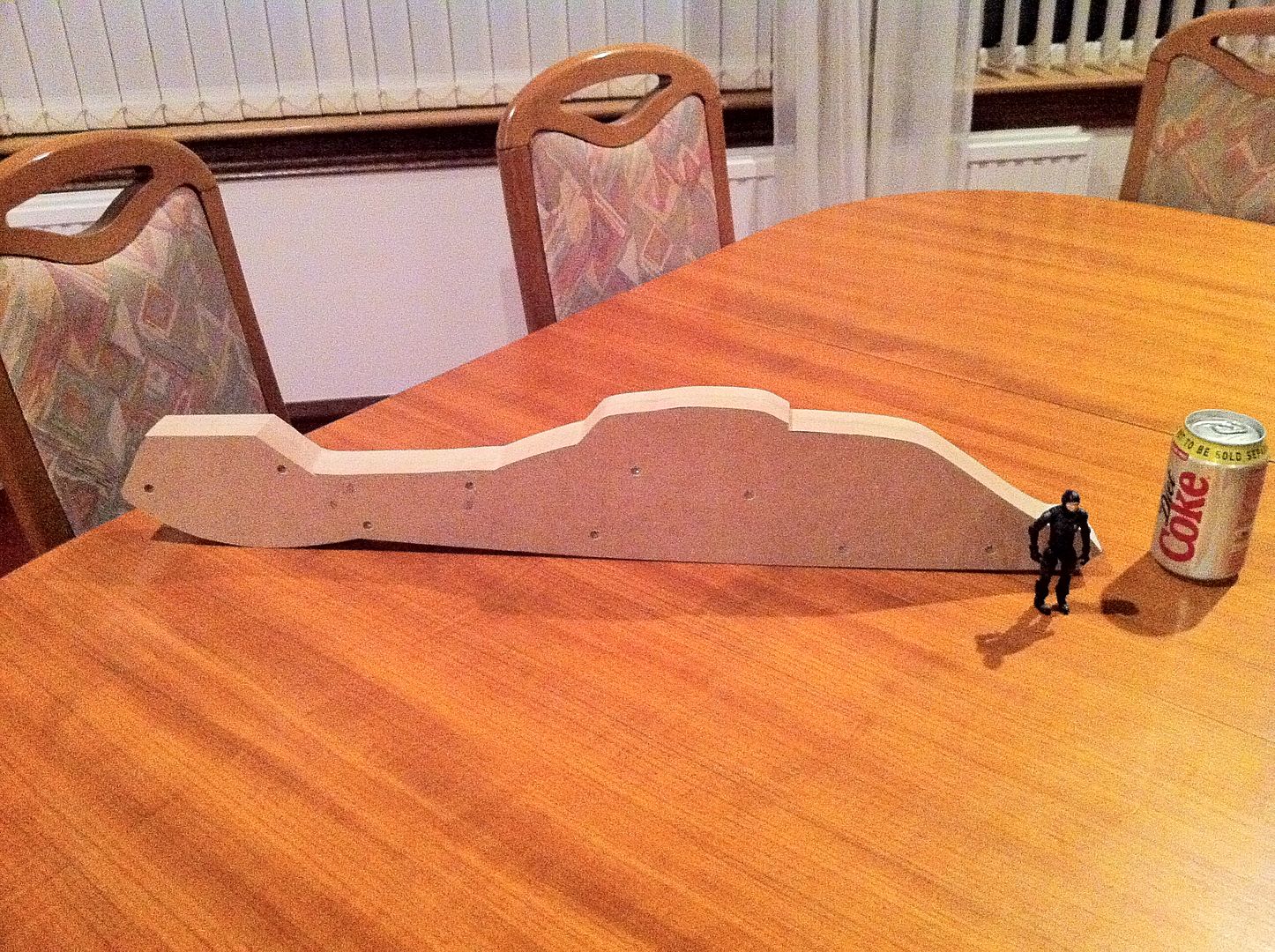

Thanks. Pics below of the cut out risers.

I have made the wings out of resin. They are hollow and are about 2 feet long with a brass rod cast into them for strength.

Very nice. Rotocasting is definitely the way to go. We did that with my F-302 kit back in the day when it was in production.

I hear you. But hey, if you can make I think all of us here would rather put $$$ in a fellow members pocket for great quality rather than some of the big guys.

Thanks a lot. I am hoping that what i make here will make people want one.

But if not, i will have one for me, and a set of patterns to make as many more as i could ever need.

Here are pics of the risers cut out together, with a Joe and a can of Diet Coke for scale: